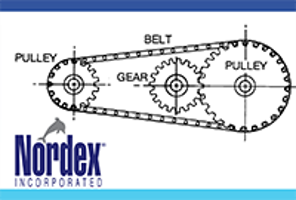

Worm/Worm shafts along with a worm wheel can provide

fine adjustment as well as a high gear reduction ratio. Another

benefit is non-movement once power is eliminated.

These systems are used in many applications such as Robotics,

Aircraft, Medical etc.

Standard sizes available as well as custom design assisted systems.