Charles Paulsen, associate director of the Mechanical and Manufacturing Technologies for Energy and Sustainability (MET2) program at the Connecticut College of Technology walked into the Nordex lobby in Brookfield, CT, on a mission. He was visiting engineering companies in the area hoping to find people interested in supporting a student project known as Prosthetics for Kids.

“The prosthetic arm created by the students was for children who were either born without an arm, lost their arm in an accident or in an act of terror in other countries,” said Lisa Barrett, sales manager at Nordex, Inc.

Nordex was excited to participate in the project because it mirrored the company’s very own engineering philosophy:

“We exist to assist fellow engineers design and bring to life new and innovative ideas,” said Barrett. “Our goal is to make a difference in the world by offering innovative ideas and fostering the philosophy that anything is possible.”

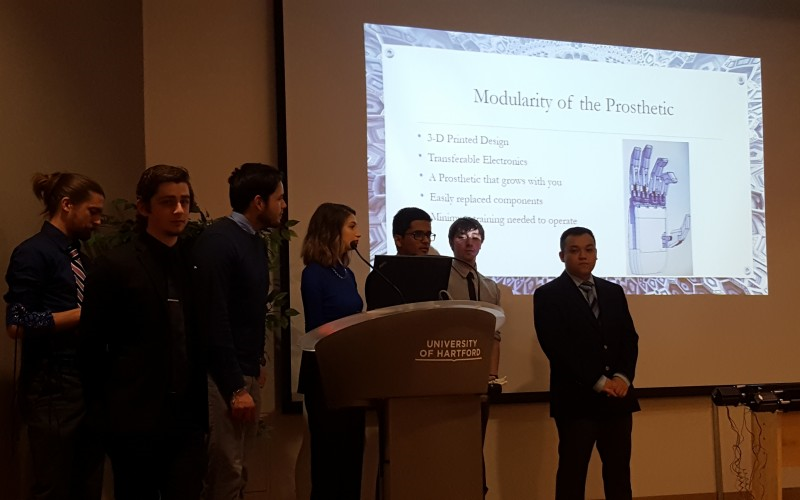

Nordex contributed parts for the Prosthetics for Kids project. Recently Senior Engineer Nick Antonelli and Barrett visited students at the University of Hartford where eight student projects were presented as part of the MET2 program.

Caption: Lisa Barrett (far left) and Nick Antonelli (far right) visited students at the University of Hartford.

“We look forward to seeing the project get funded and every child who is in need of a prosthetic arm is able to afford one,” Barrett added. She and the Nordex team were thankful for all the people that participated in these amazing projects.

In addition to Prosthetics for Kids, students presented other projects including:

The Traveling Oasis, a water purification system that was portable and could create its own power to filter and purify water.

The Green Infrastructure project which produced a versatile electrode probe kit that records water infiltration systems to monitor the success of green infrastructure for the United States Geological Survey.

Other projects included a state of the art centralized cooling system, wireless e-data and a smart guitar that incorporates microprocessor and touchscreen technology.

Barrett noted the commitment and teamwork fostered by Paulsen, John Birch, executive director of MET2 and Eric Flynn, principal investigator of the MET2 program.

“The students had so much love, respect and appreciation for these three men that helped make a difference in their lives. We were very touched at how they made themselves available day and night, seven days a week, to see their projects to completion,” Barrett added.

Nordex regularly stays active in the local community when filling job requirements. They hire students from Henry Abbott Technical High School in Danbury, Connecticut. The school offers a precision machining technology course and students start working in their sophomore and senior years and learn on the job. Many take full-time jobs at Nordex when they graduate.

The company also participates in job fairs at the University of Connecticut and offers a tuition reimbursement program.

Engineers are sent to Solidworks courses as well as other related courses depending on their knowledge and experience. “We are also a member of AGMA contributing ideas and suggestions at meetings, a board member of the National Tooling and Machining Association (NTMA), and the Connecticut chapter (CTMA) that is committed to workforce development,” Barrett said.

The student projects proved to Barrett that the future of manufacturing and engineering is in very capable hands.

“We were very impressed with the enthusiasm, professionalism and confidence of the students,” Barrett said. “Many of the students attend school full time and have part time or full time jobs. They still dedicated a lot of their time to their projects.”