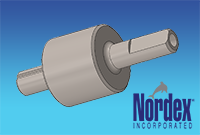

Custom Shafts by Nordex, Inc.

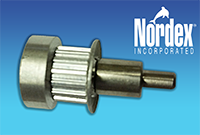

Shafts are seldom a simple round cylinder.

Special features on shafting is required for many applications.

Retaining ring grooves, flats, threaded/tapped ends, drilled holes and lubrication features.

“D” shaped shafts are an option to mount a Pulley using a Set-Screw. Keyways are used to transfer torque on high powered mechanisms.